Undercut Molding

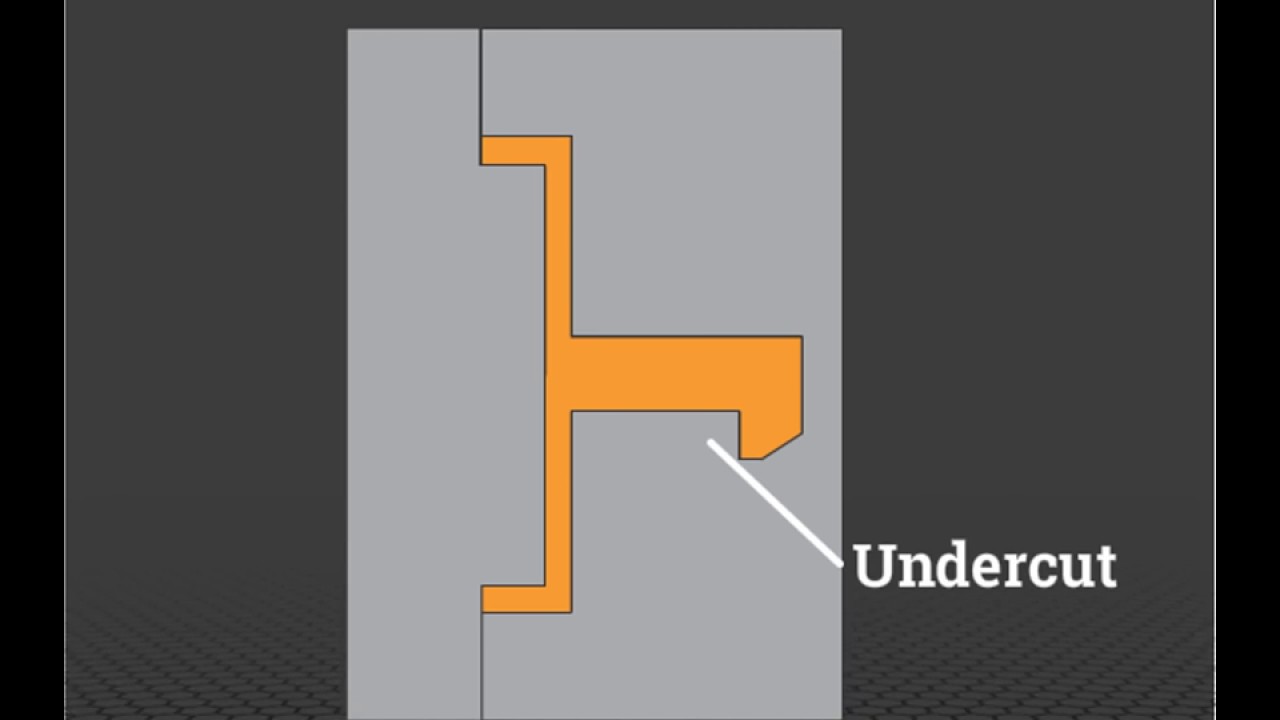

When there are through holes recesses and bosses etc. An injection molded part designed with an undercut feature means that when the mold cavity and core open there will be some plastic feature that traps some of the opening path of the metal tool.

Undercut Side Injection Mold Design Undercut Injection Moulding

At Xcentric we have the capability of producing your custom injection-molded parts with any number of undercuts.

Undercut molding. To view the undercut contribution to the indicator value click Home tab Manufacturability panel Information. It is die-locked which prevents the part from being ejected from the. Typically an injection mold is composed of two halves.

Rotational molding creates strong hollow plastic parts in a wide variety of shapes sizes textures and colors with features such as undercuts multiple walls and molded-in hardware and graphics. Undercut is indentation or protrusion that prohibits an ejection of a part from a one-piece mold. An injection molding undercut that causes damage to the part.

Undercuts on molded parts are features that prevent the part from being directly ejected from an injection molding machineThey are categorized into internal and external undercuts where external undercuts are on the exterior of the part and interior undercuts are on the. There are several ways to tackle this challenge in the tool design but most add cost and time as parts are first produced for production. The stripping undercut must be located away from stiffening features such as corners and ribs.

The Undercut element examines the part and highlights regions that could cause molding ejection problems. Undercuts achieve complex plastic part designs for the injection molding process. For example overmolding and insert molding.

With its low tooling costs and quick tooling modifications rotomolding is a good way to prototype a part. Draft alludes to the point of slope set between the vertical surfaces of the plastic moldings and the shape opening course. This months design tip covers these techniques.

While some methods for molding undercuts are tried and true they might not always provide the cost savings or efficiencies of more advanced technologies. Um exemplo simples de moldar um rebaixo externo. In molding an undercut is an indentation or protrusion in a shape that will prevent its withdrawal from a one-piece mold.

Watch the video demonstration for more information. Sometimes the easiest way to deal with an undercut is to move the molds parting line to intersect it. Undercuts can make it difficult to impossible to remove parts from molds without.

Here is the brief introduction of china high precision molds. The Draft and Undercuts in Moulding. Na moldagem um rebaixo é uma reentrância ou saliência em uma forma que impede sua retirada de um molde de peça única.

There are many more such parts all of which require a little molding legerdemainor minor part design modificationsto accommodate. This video simply demonstrates the use of side actions to solve undercuts in a part design in the injection molding process. Draft is ordinarily applied to encourage discharge of the moldings from the shape.

Undercut parts present many challenges to designers and molders but technology is always evolving to meet them. Undercuts in plastic injection molding. On the side wall of a plastic product which make it impossible to release the mold the molded product must be moved laterallywe call them undercuts.

Learn more on undercuts for plastic injection molding. Rebaixo moldagem - Undercut molding Da Wikipédia a enciclopédia livre. 6 Ways to Sidestep Undercuts in Molded Parts.

It is a feature that the cavity and core cannot capture alone. In plastic injection molding industrial it refers to part features that prevent straight ejection at the parting line which cause much mold complexity and lead to higher mold construction and maintenance costs. An undercut in injection molding is any part feature that prohibits an ejection of a part from the mold.

The undercut must have a lead angle of 30 o to 45 o degrees. Reducing the number of undercuts will reduce the cost of tooling. The injection molded part must have space and must be flexible enough to expand and deform.

Those halves come together and. 6 Ways to Achieve Undercut Success in Moulded Parts If your part design requires undercuts consider side-action cams bumpoffs inserts and other complex injection moulding techniques Undercuts are those features in an injection-moulded part that prevent its ejection from the mould. To understand why undercuts occur its necessary to understand what an injection mold is and how it works.

Whenever its possible redesign the part to avoid undercuts. The entire mechanism that drives the lateral movement of the molded product is referred to as. An undercut is any indentation or protrusion that prohibits part ejection from a mold.

Plastic Injection Mold Design Youtube Injection Mold Design Mould Design Plastic Injection Molding

Undercut Illustration Undercut Requires Multi Part Mold Design 3d Design It Cast

Collapsible Core Mechanism 4 Plastic Injection Molding Mould Design Injection Moulding

Injection Molding 101 Undercuts Youtube Injection Moulding Undercut Molding

Designing Undercuts Design Undercut Plastic Design

Collapsible Core Mold Design 10 Mould Design Molding Plastic Design

Let 039 S Discuss Undercuts Pottery Molds Mold Making Plaster Molds

Rearview Housing Injection Mold Design Undercut Mold Design On Slider Solution Concept 2 Stages Ejectio Injection Mold Design Mould Design Injection Moulding

Snap To Bracket When Undercut Is Not Possible Inzhenernoe Delo

Designing Undercuts Design Plastic Design 3d Printing Diy

Tpe Undercuts Are Possible Because The Material Is Flexible

Undercuts In Plastic Injection Molding Product Mould Design Plastic Injection Molding Molding

Undercut A Mold Made Of Plaster Is A Rigid Mold And Therefore Great Care Must Be Taken To Account For All The Undercuts In T Mould Design Mold Making It Cast

Https Ru Pinterest Com Fjborsboom Design Insipir Molding Undercuts Plastic Design Mould Design Design Rules

Rearview Housing Injection Mold Design Solutions Upmold In 2020 Injection Mold Design Mould Design Injection Moulding

Beware Of Undercuts Plaster Mold Making Mozaic

Two Plate Mould With Slider Animation Youtube Plastic Injection Molding Injection Moulding Undercut

Posting Komentar untuk "Undercut Molding"